Polishing Technology Service

Polishing Division

ElectronicPIG

- Related Business: Automotive Lighting

MEMS

- Related Business: MEMS Probe Card

Ceramic / Quartz

- Related Business: Semiconductor Equipment & Components

NanoNano Technology + Metal

- Related Business: FC-BGA, Aerospace

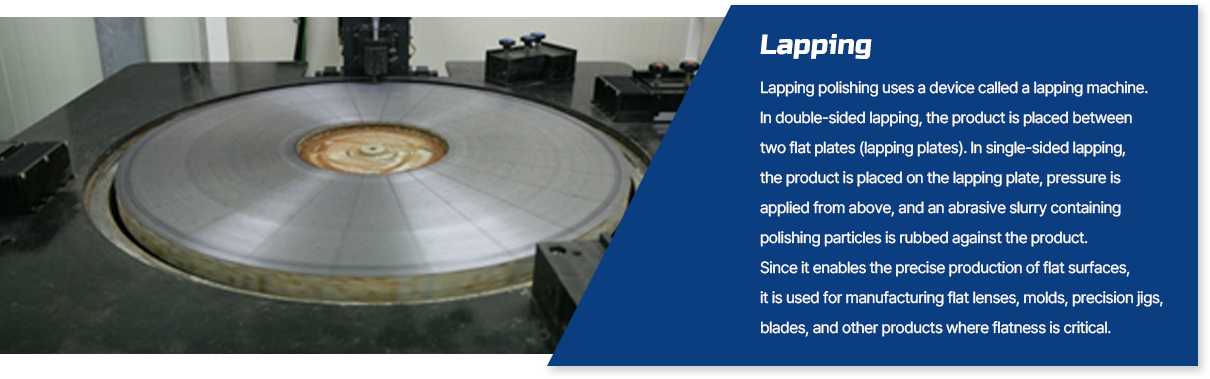

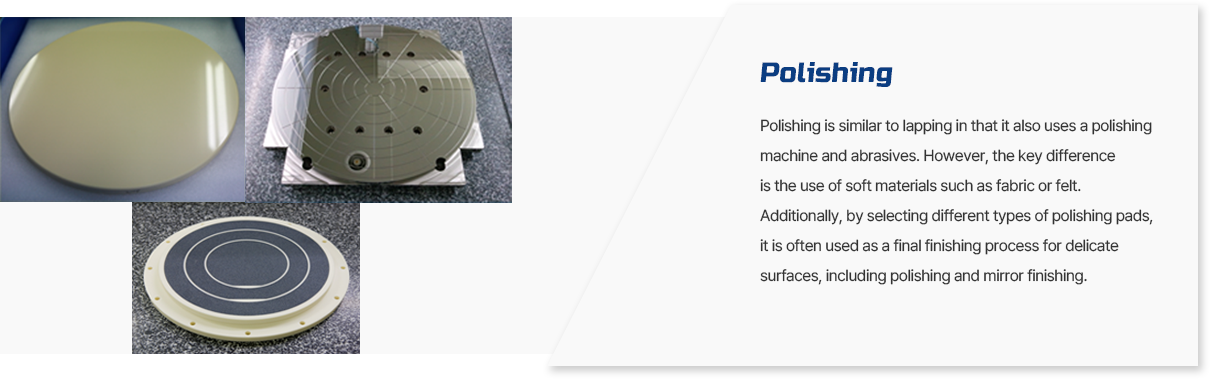

Polishing Types

Applicable Industries

Products manufactured through precision machining are used across various industries. The key industries for precision machined products include.

- Semiconductors

- Automotive

- Nano Technology

- MEMS Technology

- Industrial Equipment / Inspection Equipment / Measurement Equipment

- Optics

- Electronic Equipment / Electronic Components

- Medical Devices / Analytical Instruments

- Aerospace

- Chemical-related Equipment / Technology

- Pharmaceutical Equipment

Moreover, ultra-precision machining plays a pivotal role in the semiconductor and optics industries,

where Maryalo is a trusted partner, handling numerous high-level technical service requests.

Maryalo Polishing

At Maryalo, our precision polishing and lapping processes

feature independent rotation of the workpiece and lapping plate,

optimizing the finishing process. As polishing progresses,

the abrasive slurry refines into finer particles,

enhancing machining precision. With micron-level accuracy,

our ultra-precision techniques set the national benchmark,

delivering exceptional surface roughness, parallelism,

flatness, and dimensional accuracy

Applicable Materials

| Metal Materials | All types of steel, carbide, stainless steel, copper, titanium, aluminum, molybdenum, tungsten, nickel, tantalum, and other metals. |

| Ceramic Materials | Alumina, zirconia, silicon carbide (SiC), silicon nitride (Si₃N₄), silica (SiO₂), and others. |

| Crystal Materials | Glass, silicon, SiC (silicon carbide), sapphire, GaN (gallium nitride), quartz, crystals, and more. |

| Resin Materials | Various engineering plastics, polyimide, Teflon, etc. |

Technology Serice Product

New product/Technology development : COIN HEAD, HBM, etc.

We have forged strong partnerships with leading semiconductor and electronics companies worldwide, actively engaging in product development to drive technological innovation and optimize processes. Through this collaboration, we establish efficient mass production systems and achieve cost reductions. Additionally, by delivering advanced lapping and polishing solutions for semiconductor precision components, we ensure high-precision products and technical services that meet the highest standards of quality and durability.

Precision Polishing & Ultra Precision Polishing

Difference Between Precision Polishing and Ultra-Precision Polishing

Processes requiring high-precision polishing technology can generally be classified into two types: precision polishing and ultra-precision polishing. Precision polishing refers to polishing that achieves micro-scale machining accuracy of up to 1/1000 mm (millimeter). Ultra-precision polishing refers to polishing that achieves nano-scale accuracy at 1/1000 μm (micrometer), which surpasses the micro-scale range of a few microns to tens of microns. Ultra-precision polishing is commonly applied to semiconductor wafers, camera lenses, precision mechanical components, and optical parts. Maryalo’s advanced technology provides solutions in this field. Since nano-level machining accuracy is required, this polishing technique demands a controlled environment for temperature and humidity, as well as specialized tools and equipment. Without meeting all these conditions, achieving ultra-precision polishing is extremely difficult.

Precision Measurement

Precision measurement generally refers to the measurement or inspection of product dimensions and shapes that require precision machining technology and surface irregularity verification either during or after processing. With years of accumulated expertise and unique technological advancements, Maryalo provides ultra-precision lapping and polishing technology services. During processing, the following precision measurements are performed.

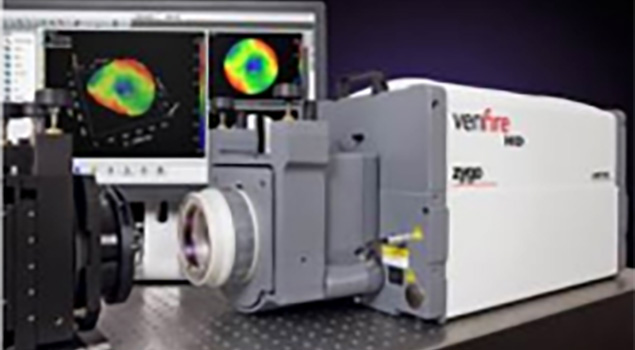

Flatness Measurement

Maryalo has received numerous orders for prototype and mass production products that require higher flatness precision than other companies. We own flatness measurement equipment such as laser interferometers and utilize them appropriately based on customer requirements and product specifications. In addition to flatness measurement, we also provide services such as flatness correction machining, precision machining according to geometric tolerances, mirror surface machining, and prototype production.

Surface Roughness Measurement

The surface of a workpiece is influenced by a complex wave pattern of peaks and valleys with varying heights, depths, and intervals. These fine waves are referred to as “surface roughness”, which affects product lifespan, mechanical efficiency, surface gloss, and texture. Therefore, in ultra-precision machining, surface roughness measurement is an essential evaluation method. There are two main types of surface roughness measurement: contact and non-contact methods. Since Maryalo possesses both types of measurement equipment, we can handle any type of surface roughness measurement.

ENG

ENG ENG

ENG KOR

KOR