Business Technology

Polishing Division![]()

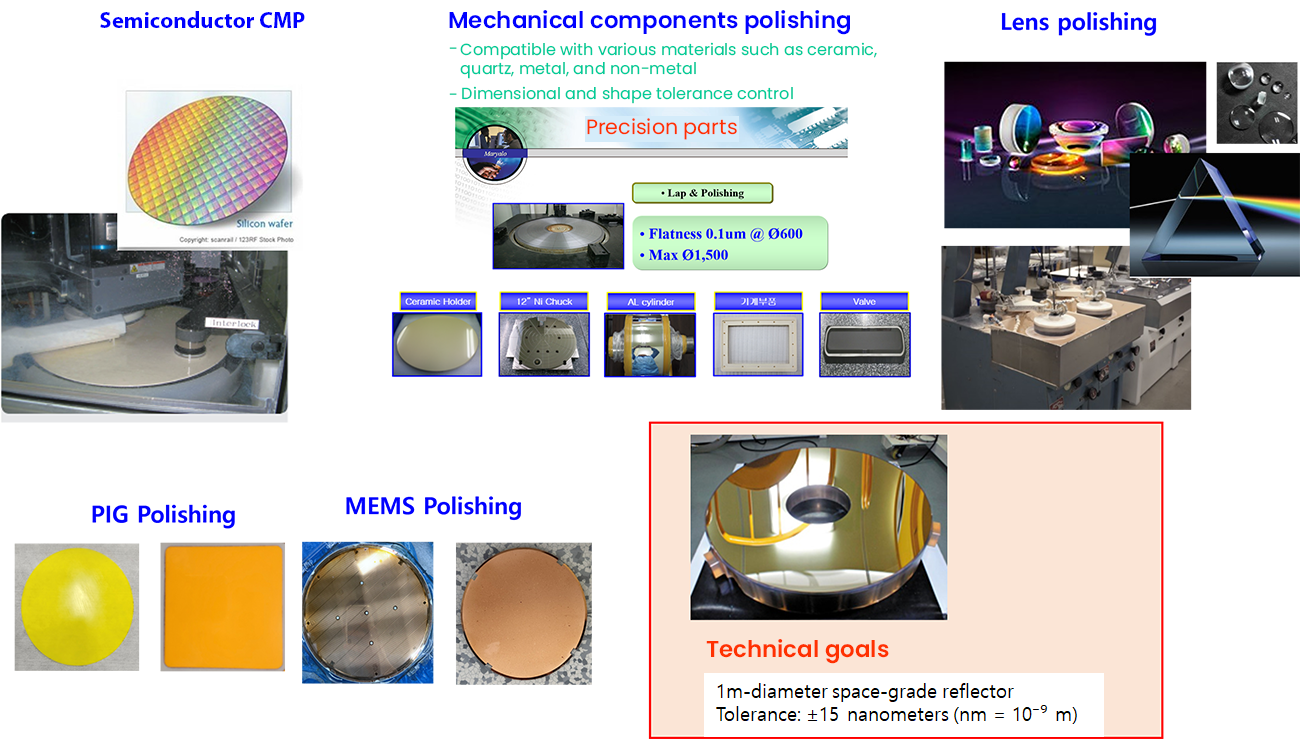

Lapping & Polishing

- PIG

- MEMS: max12” / Sapphire – 2”~8”

- Ceramic, Qurtz – Max Ø1,500㎜

- SIC Wafer & Precision parts

- MEMS / OLED / Lens / Medical Equipment

-

Lapping / Polishing / Mirror Finishing / CMP

- - Future: Defense, Aerospace, Proprietary Brand Products

Polishing Technology Services

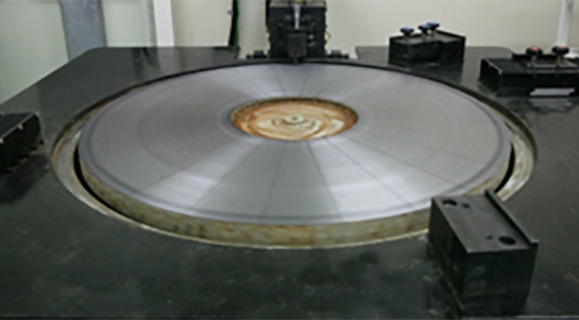

Large area polishing

![]() Φ1000

Φ1000

Quartz: Parallelism 0.01

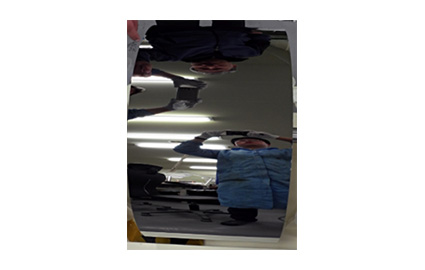

![]() Φ618×618×T10

Φ618×618×T10

Alumina: Parallelism 0.01

![]() Φ600

Φ600

Titanium G2 Roller

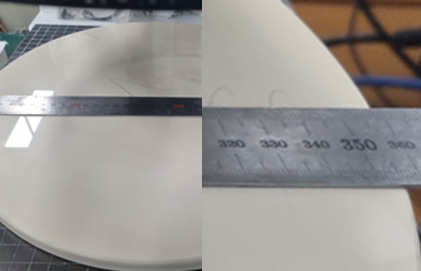

CERAMIC HOLDER

* Please slide for more details.

| Material | Measurement | Appearance | Normal |

|---|---|---|---|

| Al2O3 - 99.7% | Spec | Crack | Diameter |

|

Flatness 2um | None | Ø360±0.12 |

| Interferometer | Damage | Thickness | |

| Measure | None | 15.0 +0.2/-0.0 | |

| Φ300 Stitching | Cleaning | Corner R 3.0 | |

|

|

|

Packing |

| Individually | |||

| packaged | |||

| P-box/PE-form |

CERAMIC HOLDER

* Please slide for more details.

| Material | Measurement | Appearance | Normal |

|---|---|---|---|

| Al2O3 - 99.7% | Spec | Crack | Diameter |

|

Flatness 2um | None | Ø485±0.12 |

| Interferometer | Damage | Thickness | |

| Measure | None | 16.0 +0.2/-0.0 | |

| Φ300 Stitching | Cleaning | Corner R 2.0 | |

|

|

|

Packing |

| Individually | |||

| packaged | |||

| P-box/PE-form |

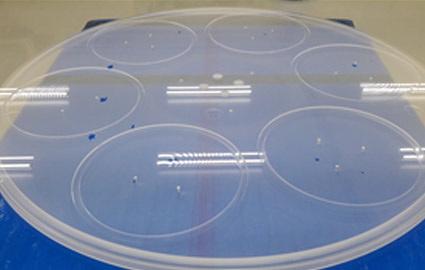

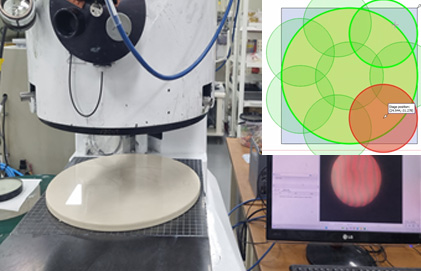

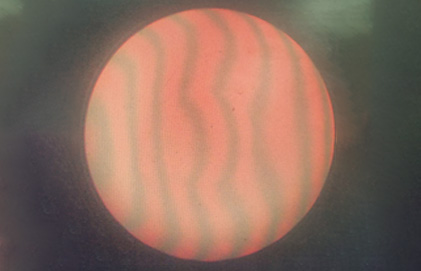

Laser interferometer measurement – flatness

![]() Using a 300mm laser interferometer

Using a 300mm laser interferometer

Large area measurement using stitching method

![]() 0.3㎛ flatness

0.3㎛ flatness

Φ360 area polishing and stitching measurement results

![]() Φ360㎜ ceramic plate

Φ360㎜ ceramic plate

ENG

ENG ENG

ENG KOR

KOR