Precision CNC Machining & Sheet Metal Fabrication

Precision Machining Division

Manufacturing

- Metal processing

- Resin processing

- Precise processing

- Processing CNC parts

- Finishing

Assembly

- Semiconductor cassette

- Equipment Parts

- Jig & Test Parts

Fabrication

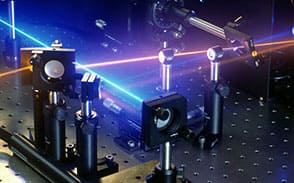

- Laser

- Welding

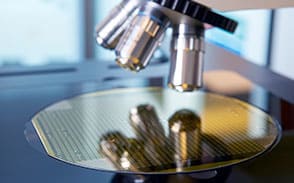

Semiconductor

- Instrument Design

- Engineering

- Simulation

1. Precision Cutting Machining Capability

- Various Machining Materials: Aluminum (AL), Stainless Steel (SS),

Steel, Special Steel, Resin, and other metals, non-ferrous metals,

special metals, and chemical materials such as resin. - Diverse Component Shapes & Structures: Capable of machining

complex shapes - Machinable Material Size: From a minimum of 1mm to over 1m, supporting both small and large-scale machining. Equipped with

large-scale machinery, 5-axis machines, and Dual Head MCT for

various sizes and mass production - Strict Tolerance: +-0.01mm

- Surface Roughness & Flatness: Ra 0.8 or better

- Wide Range of Applications: Semiconductor equipment,

LCD/Battery components, defense/optical parts,

and robotic components.

2. Applicable Fields & Superior Quality

- * Semiconductor and Electronics, LCD, Equipment Components, and Custom Precision Machining for Specialized Customer Specifications

- * In the precision machining field for semiconductor equipment components, we have accumulated the highest level of technology and quality in the country. Through research and development, we have achieved micro-hole processing advancements and export custom precision-machined components to U.S. semiconductor equipment manufacturers.

- * We have grown into a specialized R&D and high-value-added component manufacturing company for semiconductor equipment parts and materials, aiming to become a global enterprise

- * Excellent Quality Management: Certified under ISO 9001/14001 quality standards, with outstanding adaptation to global standards. Recognized as a leading company in technical management, ensuring trust and reliability for transactions.

- Collaboration and partnerships with medium-to-large semiconductor equipment component manufacturers / OEM production available.

- The quality is at a world-class level, while the price is only 60–70% of U.S. and European manufacturers. Low-cost Chinese products lack proper quality control.

- Excellent quality (machining, post-processing, polishing, etc.), with outstanding capability to handle small-batch, multi-variety, and short-term production lead times.

- Strict control over tolerances, surface roughness, and flatness, with excellent capability in various surface treatments.

CUSTOMERS

High Technology & One Stop Solution

ENG

ENG ENG

ENG KOR

KOR